Tolerance

AUTOMATIC COMPREHENSIVE PRODUCTION YOU CAN COUNT ON. UNIFORM QUALITY CONTROL IS OUR TRADEMARK.

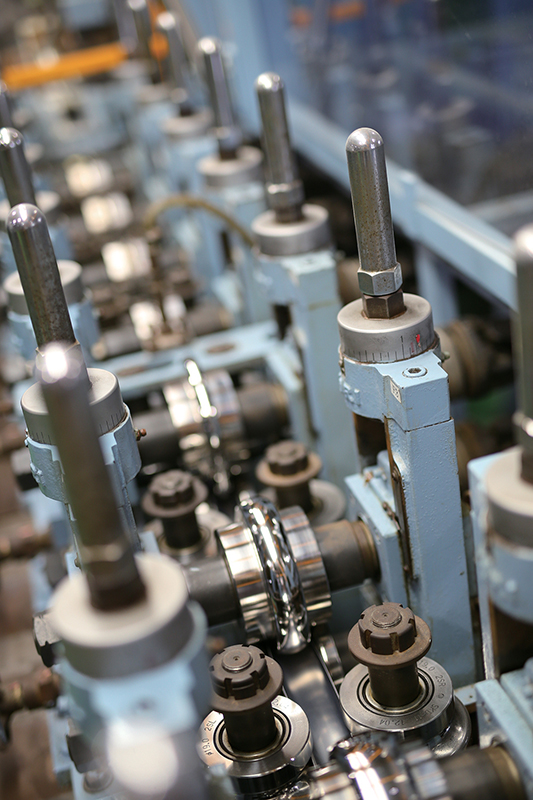

From tube production to tapering, heat treatment, plating and testing, quality control is guaranteed at every stop of the way at Nippon Shaft.

It starts with strict raw material inspection then continues with in-process controls throughout the integrated, full-scale assembly line. This uncompromising commitment to quality is just one more reason that Nippon Shaft is viewed by the top club manufacturers as the most prestigious name in lightweight steel shafts.

At Nippon Shaft, “tight tolerances” aren’t just a catchphrase—they’re measurable advantages. Our steel shafts are manufactured to weight tolerances of ±1.5 grams (versus up to 4 grams from competitors) for our top models, step lengths ±0.039” (0.125” from competitors) and step diameter tolerances of under 0.003” vs a high of 0.125” from competitors. Each shaft goes through up to 30 manufacturing stages and 20+ quality inspections to ensure exceptional consistency—shaft to shaft.

For club builders, this means fewer variables and more confidence in every build. There’s no need for extra sorting or adjustments due to manufacturing variance. You get identical performance profiles across every shaft, making the club building, shaft trimming and swingweight matching far more predictable.

Our constant weight shaft designs—where each shaft in the set weighs the same regardless of length—are available at both .355” taper and .370” parallel tips, ensuring that the feel and flex characteristics are consistent throughout the bag. This engineered continuity enables precise gapping, uniform tempo, and total trust in the final product. With Nippon Shaft, precision isn’t optional—it’s built in.